Rinaldi Group CEO, Anthony Rinaldi stopped by Fox Business News to discuss the president’s latest executive orders regarding healthcare.

The post Video: Anthony Rinaldi Talks Healthcare on Fox Business appeared first on The Rinaldi Group.

Rinaldi Group CEO, Anthony Rinaldi stopped by Fox Business News to discuss the president’s latest executive orders regarding healthcare.

The post Video: Anthony Rinaldi Talks Healthcare on Fox Business appeared first on The Rinaldi Group.

From the Commerical Observer:

BY REBECCA BAIRD-REMBA OCTOBER 18, 2017 10:00 AM

On a bitterly cold day in January, contractor Anthony Rinaldi helped organize a 500-strong rally against a City Council bill that mandated apprenticeship programs for construction workers on buildings of 10 stories or taller.

Anticipating a fight, he had hired eight armed guards to help protect the nonunion hardhats who were protesting next to City Hall. Across the street, hundreds of union construction workers were demonstrating in favor of the bill, known as Intro 1447.

“The next thing I know, the union was around the block, and they literally left their site, brought all their people and really came nose to nose with us,” he said, “and were trying to antagonize us into a riot.”

He had also given a heads up to the New York City Police Department, which dispatched a few dozen officers to quell the crowd. “It got so crazy that there were over 50 cops on the street,” he explained. “It got that dicey.”

The moment was a symbolic one for Rinaldi, who recently became chair of New York City leadership committee for the Associated Builders and Contractors, an open-shop construction trade association. It was one of his first major political fights with the group, but it certainly won’t be his last.

Even with fierce opposition from open-shop groups, the City Council passed the apprenticeship bill last month, and Mayor Bill Blasio signed it into law this week. The latest version requires construction workers to have 40 hours of safety training by September 2020.

Rinaldi’s 14-year-old construction management business, the Rinaldi Group, is open shop (meaning he can employ both union and nonunion workers) because more than 70 percent of the building permits issued in the private sector go to nonunion projects, he said. That tracks with data from the Real Estate Board of New York, which found that among residential projects with 100 or more units, only 14 percent were union sites, according to an analysis of New York City Department of Buildings permits conducted in 2015. Another open-shop group, New York Construction Alliance, told Commercial Observer in June that its seven member companies employ 75 to 80 percent nonunion workers.

It’s a little ironic that the 52-year-old Elizabeth, N.J. native spent months pushing back against the unions, after he cut his teeth working at big union construction companies in the 1980s and 1990s.

After he graduated with a mechanical engineering degree from Lehigh University—where he played Division 1 baseball—he landed his first job at HRH Construction, a subsidiary of Starrett Corporation. Starrett has built a host of well-known New York City projects, including the Empire State Building, Stuyvesant Town and Trump Tower. Rinaldi also spent several years as the chief operations officer of Crain Construction Company in Jersey City, N.J., and did a stint in the early 2000s at George A. Fuller Company, a 130-year-old, Valhalla, N.Y.-based building contractor.

Despite his rising star in the open-shop, or merit shop, world, “we have the ability to go union as well,” he explained. “I come from union backgrounds. My father-in-law was a Local 79 laborer. My father was a cop. If there was a project where the developer wanted to do the job union, under a project labor agreement we could do the project union. But when you’re union, you can’t go the other way.”

Besides his foray into industry politics, Rinaldi is working on several interesting construction projects. On Bowery between Spring and Delancey Streets, his firm is building the tallest modular hotel in the world for Dutch hotel developer Citizen M.

To build the 20-story, 300-room hotel, Polish modular manufacturer Polcom shipped 220 pre-assembled pods, complete with fixtures, plumbing and electricity, across the Atlantic Ocean. Now Rinaldi’s workers are stacking them on top of a concrete foundation, connecting the plumbing and electrical to the building’s mechanical systems, and fitting the facade pieces together.

Developers tend to assume that modular construction is cheaper, but the hard construction costs are typically the same, “dollar for dollar,” he noted. “Where it does get cheaper is in the timing.” While workers excavate and lay the foundation—a process that usually takes four to eight months—the modular units are being manufactured.

“So you’re actually able to make the rest of the building somewhere else and not having to wait for linear progression of the construction after you come out of the ground,” he said. “Those units are now there and you can stack them. It will take anywhere from four to six months off your schedule.”

Developers get to pay off their construction and property loans faster than they would be able to with a conventional construction project, and their building begins producing income sooner. There are also fewer months of disruptive construction for the neighborhood.

A little further uptown, Rinaldi is helping Empire Management redevelop a landmarked bank at 250 Fifth Avenue at the corner of West 28th Street. The bank is being expanded from eight to nine stories and converted to retail and office space. Then a 23-story, high-end Thompson Hotel will sprout behind it on West 28th Street.

He also recently topped out a 38-story hotel developed by the Lam Group at 215 Pearl Street in the Financial District. And over the past year and a half, Rinaldi Group has wrapped up construction on two major hotels, a 30-story, 150-key Hyatt House at 101 West 28th Street and the 31-story, 641-key Riu Hotel at 301 West 46th Street in Times Square.

Outside of the tristate area, he’s working on the redevelopment of the historic Collins Park Hotel in Miami Beach for Chetrit Group. Before that, his firm finished a 36-bed retirement home in Lake Worth, Fla.

The one black mark on Rinaldi’s long career as a construction manager happened at the Riu Hotel site two years ago. On May 5, 2015, a worker named Christian Ginesi and a colleague were installing elevator doorframes when the temporary hoist Ginesi was working on stalled between the 24th and 25th floors, the New York Daily News reported. The other construction worker was able to successfully jump to the 24th floor below. But Ginesi unclipped his harness, which was supposed to be attached to a steel beam or to a cable system at the top of the shaft but wasn’t, and then tried to jump down, Rinaldi said. The 25-year-old Jersey City resident ultimately slipped and fell down the shaft, dropping 26 stories to the basement. He was rushed to Bellevue Hospital, where he died an hour later.

Union officials slammed Rinaldi and the elevator subcontractor that employed Ginesi, G-Tech, for not offering the proper training.

“The young man had just got back from [serving five years with the Air Force in] Afghanistan, and he had no training whatsoever,” said Gary LaBarbera, the head of the Building and Construction Trades Council of Greater New York. “They take advantage of unskilled workers, and that’s the kind of company Rinaldi Group is.”

Six months later, the DOB suspended Rinaldi’s contractor license, halting work on all 17 of his sites across the city. He claimed it happened without any prior notice.

A spokesman for the DOB stated that the agency “suspended Rinaldi’s license because he had 55 serious safety lapses at 8 sites over two years.”

Rinaldi argues that the city’s decision to pull his license was politically motivated. “The unions and self-interested bodies took advantage of it to try and smear me every which way they could,” he recounted. “I was being classified in the papers as a troubled contractor. The truth was that I had an impeccable safety record up until that time.”

A month later, the city’s Environmental Control Board, an administrative court that hears building violations, reversed the suspension and ruled that Ginesi’s death had occurred because of human error (unclipping his harness).

In spite of the scandal, Rinaldi is generally well liked in the construction industry.

Marshall Adams, a lawyer who represents Rinaldi in Florida and a close friend, called him a “warm, engaging, funny guy” and “the most brutally honest client I have.” The pair met six or seven years ago when Rinaldi brought him a case involving a subcontractor.

“I analyzed his case and said the subcontractor did all these bad things, but you’re going to have to make good on them,” Adams explained. “And he said, ‘I brought this guy to the table, I have to make good on all the things he did.’ It makes it easy to represent a client when they listen to you and are willing to do the right thing, [when] they’re not just trying to find a way out.”

Rinaldi has a wife, Joan, of 28 years, and three kids, 15-year-old Julia, 19-year-old Frankie and 22-year-old Anthony. The family often visits Adams and his children in South Florida over the holidays. “My kids love him, and they love his wife,” Adams said. “And we try to make it a point to see each other when I’m in New York.”

Danny Khazai, a stone importer who heads NYC Worldwide Marble, echoed those sentiments. He met Rinaldi in 2003 when they were both working on a Ritz Carlton in White Plains, N.Y. In a city full of shady contractors, Khazai described him as honest and reliable.

“He’s one of the only people who makes sure that the job gets done on time, and that all of the subcontractors get paid on every job,” Khazai said. “In our industry, what happens is, 90 percent of general contractors, they end up not paying you. That’s how this industry is.”

But Rinaldi still holds his subcontractors to high standards and pushes them to finish work on time. “When it comes down to business and his projects, you have to get done on time,” Khazai said. “If you’re behind, he’s hard on you.”

In many ways, it’s clear that Rinaldi was shaped by his father, who served on Hoboken’s police force for 33 years (and in classic Italian fashion, was also named Anthony Rinaldi). He retired in 1982 as the highest-ranking captain in the small city’s police department. Two years later, during Rinaldi’s freshman year at college, he died of colon cancer.

One of the contractor’s early memories involves his mother, who panicked after not being able to reach his father and drove into the middle of a race riot in Hoboken in 1970.

“They were still having some of the residual riots going on that were coming from Newark and Jersey City,” he remembered. “My mother was worried, couldn’t get him, so she puts me in the car—I had to be 4 or 5—and drives right into one of the riots. I saw my dad in riot gear, the helmet with the shield. And they were shooting at [the cops] from the rooftops. This was Hoboken. It was like crazy. My father actually saw my mother drive by. And my father went nuts; he was crazed. That’s how rough Hoboken got.”

Later that year, their family decamped to Secaucus, N.J., where Rinaldi has lived ever since.

Read more from the Commercial Observer…

The post Meet Anthony Rinaldi, the Contractor Building the World’s Tallest Modular Hotel appeared first on The Rinaldi Group.

From The Real Deal

Rinaldi talks baseball, union labor and what it’s like dealing with a death on a construction site

The world’s tallest modular hotel, according to its builder, is also the “worst nightmare” for union construction companies.

“Modular to the unions is hell on earth. It’s like their worst nightmare because everything’s being built in a factory faster, cheaper and without union labor,” said Anthony Rinaldi, head of his eponymous firm, the Rinaldi Group. “This project, CitizenM, is the epitome of everything they hate.”

Rinaldi, 52, who founded the Rinaldi Group in 2003, is a proponent of open-shop construction — meaning a labor force that includes both union and nonunion workers. Rinaldi recently became regional chairman of the open shop group, the Associated Builders and Contractors, which has been a vocal opponent of the construction safety bill passed by the City Council in September.

The 100-plus-person firm is working on a dozen projects in the city, including the CitizenM hotel, a 20-story modular hotel on the Lower East Side. The company, which is based in Secaucus, New Jersey and has offices in Manhattan, focuses on rental, condo and hotel projects in the city, New Jersey, Florida and Arizona.

Rinaldi graduated from Lehigh University in 1988 with a degree in mechanical engineering. He worked at several construction firms — including Cross Bay Contacting, HRH Construction and Crain Construction Company — before setting out on his own. He and his wife, Joan, have been married for 28 years, but they started dating when they were juniors in high school. They live in Secaucus with their daughter, Julia, who is in high school, and they have two older sons, Anthony and Frankie, who are both in college.

As part of a new questions-and-answers series with construction bosses in New York City, The Real Deal sat down with Rinaldi in his company’s New York office at 125 Maiden Lane. He answered the following in a New Jersey accent:

The bio on your website says your mom was an amateur bowling champion. Tell me more.

She was once recruited to go on a pro-bowlers tour. It was a lot of traveling, and one of those things, and my father wasn’t so hot on it. So, she didn’t do it. But she’s in the amateur bowlers women’s hall of fame. Believe it or not, they actually have something like that. She had state records forever, and certain county records that lasted for 23 years.

Your father was a police officer in Hoboken. What was it like growing up the son of a police officer?

He was probably one of the most brutally proud cops I’ve ever seen. He was militant. He was a proud American, he was a proud cop and he was disciplined. He was the kind of cop who wouldn’t even take Novocain for a cavity because it was a form of a drug. This was an influence because as a kid, you want to be like your dad. So, I finally get my first cavity, I’m going to do what my dad does, right? I’m not going to have any Novocain. I was on the ceiling. So, my entire life, I’ve only had two cavities. The second one, I took the Novocain.

What made you want to go into construction? Did you ever consider following in your father’s footsteps?

I really didn’t think about going into the police force. My father came from a different era, didn’t go to college but was very well-read and believed in education. When he took the police captain’s test, he actually placed first, and he beat out a lawyer. He was proud of that, being a layman. Growing up, I was very good in math and science. As I got older, the two professions that I was looking at was either engineering or accounting. And I certainly felt like I wasn’t built for accounting. I liked to be around action.

You played Division 1 baseball at Lehigh. Did you ever consider going pro?

I actually had three major league tryouts. I had a tryout with the [LA] Angels, the LA Dodgers and the Cleveland Indians. Long story short, I had tryouts but nothing panned out from that. I would’ve liked to try to pursue it. I don’t know how far I could’ve gone. But, with my dad passing while I was in college, I was an only child, my mom needed me, and I needed to get a job. My life’s plans got a little bit sidetracked.

One of the jobs you worked on at HRH Construction was the Audubon Ballroom in Harlem, where Malcolm X was assassinated. As part of the public-private project, you preserved part of the theater and also constructed a new research center for Columbia University. What do you remember from that time?

When we were bidding the job, I walked onto the floor where he was killed. You could see the bullet holes in the podium. I actually said to one of the guys, “You listen to me. We get this job, the first thing we’re doing is we’re taking all of that, and the guy from the Economic Development Corporation was behind me and says, “You’re not touching any of that. This stuff is going to be artifacts.” I says, “I thought you guys were leaving this to be demolished.” He says, “No way, as the contractor, you’re going to be carving all of this out, and we’re going to be salvaging that.”

After HRH, you joined Crain Construction in Jersey City, but things ended acrimoniously with the owner. What happened?

Between 1996 and 2002, I worked my way up in the company from a vice president with a 20 percent stock to becoming actually president and 50 percent stock. Unfortunately, at that time, the original investor, who created this company, wants to take a different direction. Meanwhile, he had very little involvement with the company other than the financial side of it. We didn’t see eye-to-eye at that point. I tried to buy the company from him, but he wouldn’t sell it to me. So, I was left with a really difficult decision. What we wound up doing is, literally overnight, I closed the doors on a Friday night as Crain Construction, and Monday morning we opened up as the Rinaldi Group in 2003. Every single person who was in that company at the time came with me.

In 2015, the Department of Buildings briefly suspended your license following the death of Christian Ginesi, who fell 24 stories at your construction hotel site at 301 West 46th Street. What happened after your license was suspended?

Once we were able to sit down with the Building Department and show them the number of things that we were doing even prior to that incident, we were able to show them the facts of the case, you know, what really happened, which was human error. I was finally able to get my day in court. We ultimately were exonerated.

What was it like dealing with the perception that your company was unsafe?

I’ve been through a lot of difficult times in my life. Losing my dad, that was a difficult time. Trying to juggle a baseball scholarship with engineering at Lehigh, I thought that that was hard. I actually went to a fat farm for a month, and I thought that that was difficult. But going through that experience, and the rush to judgment, and then trying to get back what took a lifetime to build up, a reputation, was a difficult task. All too often what happens is an issue like that becomes a political football.

How did it impact your business?

It was a tough bell to un-ring. With the exception of one project at the time, we didn’t lose one project. Even with that one project, the only reason that that happened was it was with a client that we were doing three projects with at the same time. The lender got a little squeamish. They didn’t take all three projects from us, but the lender said in light of the fact that [the company’s] got a couple potential issues, let’s not put all of our apples in one bushel. That client, to their credit, stuck with us on the other projects, and we’ve done repeat work with them since. All of our clients stayed with us because they knew that we were the same company that we were before that incident.

Why have you and your family stayed in Secaucus?

My wife, she’s got two sisters, and all of them live in town. We still live blocks away from each other. They are, the three sisters, on the phone with each other every day at 10 o’clock in the morning. I’m like, I don’t get it, what could you possibly cover all these years, that you haven’t covered before? But they are a tight-knit family, and she did not want to relocate. I grew up in Secaucus, New Jersey. I’m going to live and die in Secaucus, New Jersey.

Read more from The Real Deal

The post The Real Deal – Stop, hammer time: Q&A with NYC construction boss Anthony Rinaldi appeared first on The Rinaldi Group.

Founder and President Anthony Rinaldi talks tax reform with Fox Business News’ Stuart Varney

The post Video: Tax Reform and New York’s Construction Business – Anthony Rinaldi on Fox Business News appeared first on The Rinaldi Group.

UPDATE 12/19/17: Anthony Rinaldi on 1010 WINS News Radio: WHAT: Topping Off ceremony for the new CitizenM hotel, now the tallest modular constructed hotel in the world WHEN: 12:00 Noon Tuesday, Dec. 19, 2017 WHERE: 189 Bowery, New York, NY Contact: Matt Sheldon (917) 280-7329 New York (NY) – New York City and State officials will join members of the Rinaldi Group at 12:00 noon on Tuesday, Dec. 19th, 2017, to celebrate completion of the new CitizenM Bowery – the nation’s largest modular-construction hotel project ever. There will be an official topping off ceremony to mark the finish of the last floors of the hotel. The high-rise 300-room hotel was built through an extraordinary process. Sealed units containing fully-finished hotel rooms were factory-made and stacked together. The rooms were shipped in 210 pieces to New York. The Rinaldi Group is the project manager. “We are extremely proud of the work we have done on the citizenM Hotel,” said Anthony Rinaldi, chief executive of the Rinaldi Group. “The building is state-of-the-art and will be the forerunner of similar types of structures in the future.” The modular-construction process, popular in Europe and gaining in use throughout the United States, allows for faster building – generally about half the time as for traditional construction. The number of truck deliveries is also cut by about half as well, thus significantly lowering the impact on the surrounding neighborhood. The new hotel is considered to be the “Crown Jewel” of the Lower East Side which is quickly becoming one of Manhattan’s most vibrant neighborhoods. With NYC predicted to see a record 61.8 Million tourists in 2017, it is expected that business travelers and tourists alike will come from all around the world to enjoy the many amenities of NYC’s newest and hippest hotel with its international vibe. CitizenM will offer an exterior and interior rooftop bar and lounge called CloudM with sweeping 360 degree views of the Manhattan skyline. There will also be a fitness center, a double-height lobby, lounge and café at the property. Read more about this project here…

NATION’S LARGEST MODULAR HOTEL AT 189 BOWERY DEBUTS AHEAD OF GRAND OPENING IN NYC’S NEWEST BOOMING NEIGHBORHOOD

VALUE

$63,674,475

SIZE

20 Story, 300 Guestroom hotel, rooftop bar

ARCHITECT

The Stephen B. Jacobs Group, P.C.

STRUCTURAL ENGINEER

DeSimone Consulting Engineers

MEPS ENGINEER

Edwards & Zuck Consulting Engineers, PC

GEOTECHNICAL ENGINEER

RA Consultants LLC

DEVELOPER

OSIB-BCRE Bowery Street Holdings LLC

OWNER

citizenM Hotels

PROGRESS

78%

The post NATION’S LARGEST MODULAR HOTEL DEBUTS AHEAD OF GRAND OPENING IN NYC’S NEWEST BOOMING NEIGHBORHOOD appeared first on The Rinaldi Group.

From WPIX:

The building rises on the corner of Delancy Street and Bowery.

Part of it was built in Europe.

More than 200 parts, including the rooms and corridors were made in Poland and shipped to New York City where they were stacked and connected. Workers dug and constructed the foundation and first three levels.

Crews have been working for a year on the citizenM Hotel. It rises taller than other modular hotels, officials say. The contractor is The Rinaldi Group.

Anthony Rinaldi says the modular building allows for a shorter construction time.

This week, they commemorated the topping out the building with a ceremony on the roof, with 360 degree views of downtown.

It will open in 2018.

Read more about the project here…

The post VIDEO: WPIX11 on Rinaldi Group Nearing Completion of Modular Designed CitizenM Hotel appeared first on The Rinaldi Group.

HAP 10 is e a luxury rental property, designed by Karl Fischer Architects, consisting of 108 rental units, a modern gym and 61 parking spaces.This project will allocate 20% of its rental units for affordable housing as part of NYC’s 421a program. HAP 10 is also participating in the FRESH program with a first-floor supermarket, which provides developers with incentives to bring supermarkets to underserved areas. Located in the evolving East Harlem community, 2211 Third Avenue is a short walk from East River Plaza, a commercial center housing Costco, Target, and Best Buy. Local schools, universities and hospitals are all within walking distance of the property, as well as Thomas Jefferson Park, which has a pool and recreation center open to the public. Residents will have a short walk to the 4,5,6 subway for an easy commute to midtown Manhattan and the 125th Street Metro North train station serves commuters traveling to upstate New York and Connecticut.

VALUE

$38,801,890

SIZE

12 STORY Ground Up / 108 Apt. Units / 136,736 SF Residential w/ Ground Floor Retail & Community Center

ARCHITECT

KARL FISCHER ARCHITECTS

STRUCTURAL ENGINEER

Titan Engineers, PC

MEPS ENGINEER

TSF Engineering, PC

GEOTECHNICAL ENGINEER

Becker Engineering

OWNER/DEVELOPER

2211 Third Avenue Mazal LLC

PROGRESS

100%

The post HAP10 Video Walk-Thru – See Inside Recently Completed Rinaldi East Harlem Project appeared first on The Rinaldi Group.

From Commercial Property Executive:

Working on behalf of Brack Capital Real Estate and CitizenM, general contractor Rinaldi Group is quickly approaching the completion of the 300-key CitizenM Bowery Hotel.

The use of modular construction continues to pick up steam in the U.S. hotel sector, and CitizenM Bowery Hotel in Manhattan is among the latest evidence of the trend. With the Rinaldi Group aboard as general contractor, Brack Capital Real Estate and hotel chain CitizenM Hotel just topped off the 300-key lodging destination, which will be the largest modular hotel in New York City.

Construction of the 100,000-square-foot CitizenM commenced in 2015 at 189 Bowery. Stephen B. Jacobs Group designed the hotel, and as noted on the architecture firm’s website, the original concept for the property was not centered on modular construction; it was originally conceived as a conventional, poured-in-place concrete structure before the developer decided to go in a different direction.

Per the modular construction process, the hotel is being built with pre-engineered units produced in a factory—in this case, in Poland—and delivered to the development site. “For the Bowery project, modular construction has allowed for a significant reduction in the number of trips for delivery of materials through the congested streets of Manhattan, reducing construction time by several months,” Susan Furbay vice president for business development with HVS, noted in a recent report by the hospitality consulting services firm.

NOT JUST A FAD

A growing number of developers are going modular in the hospitality sector, and dollar signs have more than a little to do with the movement. “While modular construction is not necessarily a cost-saving initiative from a labor and materials standpoint, the cost savings result from the shortened project timeline,” per HVS’s new hotel development cost survey. “Modular hotel projects save approximately two to three months in total construction time, which can be as much as a 10 to 15 percent time savings.” Additionally, modular construction allows for a reduction in waste, labor, as well as construction site theft.

Among the hotel companies that are boosting their modular projects is Marriott International, which announced a comprehensive expansion of its modular construction initiative in North America in May 2017. The company plans to employ the fairly progressive construction method on approximately 13 percent of all development deals in the region this year, which would mark an industry first in North America.

With the last beam having been positioned atop the 20-story CitizenM, Rinaldi is on track to complete construction of the lodging destination in early 2018.

Read more from Commercial Property Executive…

The post Commercial Property Executive: NYC’s Largest Modular Hotel Tops Off appeared first on The Rinaldi Group.

From For Construction Pros.com

Rinaldi Group is quickly approaching completion of the 300-key citizenM Bowery Hotel, with big modular savings coming in the form of faster delivery time

The use of modular construction continues to pick up steam in the U.S. hotel sector, and citizenM Bowery Hotel in Manhattan is among the latest evidence of the trend. With the Rinaldi Group aboard as general contractor, Brack Capital Real Estate and hotel chain citizenM Hotel just topped off the 300-key lodging destination, which will be the largest modular hotel in New York City.

The 100,000-sq.-ft. citizenM was designed by Stephen B. Jacobs Group, originally as a conventional, poured-in-place concrete structure. The developer decided to pursue modular efficiencies.

Pre-engineered units produced in a factory in Poland are delivered to the site for assembly. “For the Bowery project, modular construction has allowed for a significant reduction in the number of trips for delivery of materials through the congested streets of Manhattan, reducing construction time by several months,” Susan Furbay vice president for business development with HVS, noted in a recent report by the hospitality consulting services firm.

Marriott International is also among hotel companies expanding modular construction in North America.

Read more from For Construction Pros.com

The post For Construction Pros: Topping Off NYC’s Largest Modular Hotel Underscores the Modular Trend appeared first on The Rinaldi Group.

Rinaldi Group CEO and Founder, Anthony Rinaldi talks to Fox Business’ Stuart Varney about America’s booming construction industry.

The post Anthony Rinaldi on Fox Business – America’s Construction Boom appeared first on The Rinaldi Group.

Rinaldi Group President and CEO, Anthony Rinaldi talks about the need for U.S. infrastructure improvements on Fox Business.

The post Video: Anthony Rinaldi Talk Infrastructure on Fox Business appeared first on The Rinaldi Group.

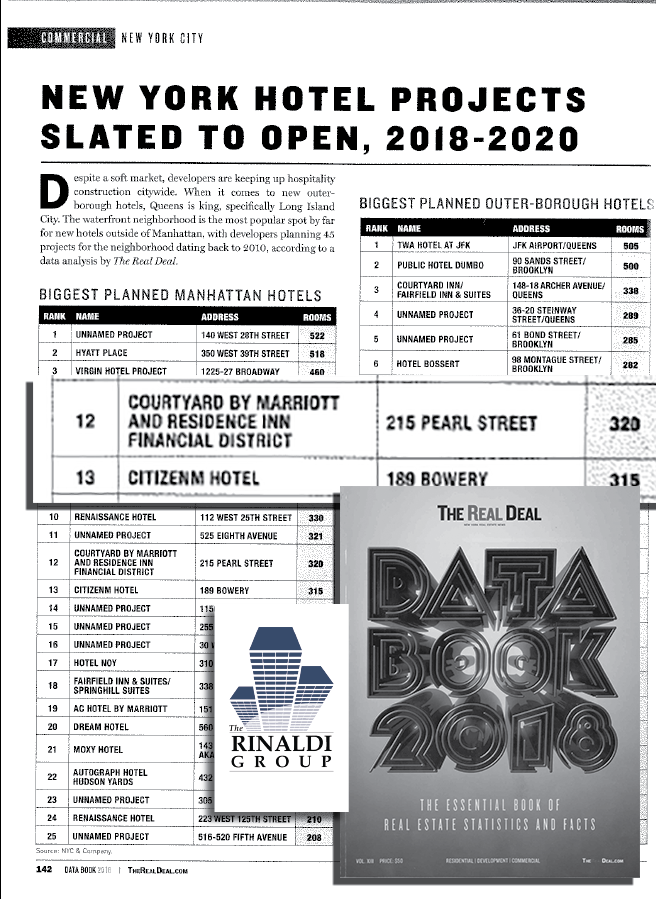

The annual Data Book by The Real Deal is hot off the presses and among the rankings for “Biggest Planned Manhattan Hotels” are two Rinaldi Group projects, ranked 12th and 13th respectively. Those projects are The Courtyard by Marriott at 215 Pearl Street and the Citizen M Hotel at 189 Bowery – also the largest modular hotel in the city.

The Data Book 2018 arrives with the February print issue and can be found on newstands….

The post Rinaldi Group in The Real Deal’s 2018 Data Book appeared first on The Rinaldi Group.

Long Beach, CA – After helping to grow ABC’s New York Empire Chapter faster than any chapter in the national organization, Builder, Engineer and President of The Rinaldi Group, Anthony Rinaldi was awarded the Beam Club Presidential Award at the association’s annual convention.

In his speech, Mr. Rinaldi recounted how the merit shop’s struggles in New York City paved the way for greater safety standards for the entire city – union and non-union.

The ABC Empire Chapter was also honored for:

Read more about ABC Empire Chapter here. More about Anthony Rinaldi here…

The post Anthony Rinaldi Honored by Associated Builders and Contractors appeared first on The Rinaldi Group.

From Modern Home Builder:

The Rinaldi Group (TRG) is a full-service general contractor and construction management firm based in Secaucus, N.J., with satellite offices in New York City and Miami Beach, Fla. CEO Anthony Rinaldi started the company in 2003 after leaving Crain Construction, where he served as vice president, and later president, during an eight-year tenure dating back to 1996.

Rinaldi notes that although he left due to “irreconcilable differences” with the owner, he enjoyed playing a key role in helping Crain maintain business in excess of $100 million at the time.

Fifteen years later, TRG has earned a reputation for performance and execution. The company has more than 100 employees and focuses primarily on high-rise commercial hotels, and residential and office buildings in the private industry sectors. With more than $600 million worth of projects in its pipeline, TRG has come a long way from its early days of constructing sidewalks and curbs.

“I literally had to start all over again with nothing after Crain,” Rinaldi explains. “We have worked our way up from curbs to building 40-plus-story buildings throughout New York City. It’s been a long road and we’re very proud of our company.”

Keys to Success

Rinaldi’s background includes working for two of the country’s largest union general contracting and construction management firms, HRH Construction and George A. Fuller. In addition, over the past decade, there has been a significant shift from union to non-union labor in New York City, Rinaldi notes. He adds that more than 80 percent of permits for private projects today are in the non-union sector.

Ultimately, TRG has grown because of its work with non-union labor. “We are not only known among the largest non-union builders, but also the largest builders period in New York City,” Rinaldi says. “I believed this would set us apart from the beginning. I wanted to offer clients the technological ability and capabilities of the big union companies in a non-union setting.”

TRG was “operating terrifically” until 2008 when the market crashed, he relates. The company went from having eight projects in its pipeline to only two.

“Despite that, no one was laid off,” Rinaldi recalls. “We decided that we were all going to take pay cuts, including me. I told everyone that when it was over they would have their normal salary again. By 2011, I was able to do that and more. Since then we have never looked back.”

TRG has a strong, family-like culture, Rinaldi says. “We don’t have a lot of turnover,” he says. “The people who are with me today have been with me since the beginning. There are even some from Crain and beyond that. Our culture is great and they have contributed to our success.”

TRG also has longstanding relationships with its subcontractors. “A lot of these trades have become friends of ours,” Rinaldi says. “The relationship has gone from corporate to personal. These are longstanding relationships that, we believe, will stand the test of time.”

High Standards

TRG has the ability to perform much of a project’s work with its own in-house labor and equipment led by civil, electrical and mechanical engineers, licensed professional engineers and architects, certified and licensed cost engineers and estimators, OSHA-certified and New York City Department of Buildings licensed site safety managers, and project managers and superintendents.

“We also have field professionals that supervise the quality of the mechanical, engineer and plumbing trades,” Rinaldi says. “We cover every base at TRG to ensure we meet our clients’ needs.”

TRG not only has complete control of any project and its owner’s critical schedule, but also ensures the quality and integrity of a project through tight adherence to the architect and engineer’s drawings and specification requirements.

The company utilizes state-of-the-art tools – including Microsoft Projects and Primavera Suretrak – and monitoring techniques for project progress and development. In addition, TRG utilizes Revit, building information modeling (BIM) and CAD programs, which provide 3-D modeling for coordination between the different building disciplines and systems such as structural, architectural, mechanical, plumbing, sprinkler and HVAC design drawings.

“Whether we’re using CPM logic and scheduling techniques or Gantt bar-chart methods and analysis, our actual project performance is continually measured and monitored,” Rinaldi explains. “By constantly analyzing this information, we maintain the ability to proactively address scheduling fluctuations if and when they occur.”

Although TRG begins scheduling pre-award, scheduling is discussed “in great detail” with its employees, subcontractors and vendors. In fact, a potential subcontractor and vendor is not only evaluated for their pricing, but they are also qualified based upon their ability and commitment to perform the project within the planned constraints of the project. “We have bi-weekly coordination meetings throughout the term of the project, which enables a true teamwork focus and feeling,” Rinaldi says.

In addition, TRG applies tight controls when it comes to cost management. Cost control begins at the construction estimate, which follows the Construction Specifications Institute’s (CSI) divisional cost coding for all AIA trade classifications. TRG builds and purchases each construction item and activity directly from this well-detailed document.

“These baseline estimates are done using Timberline Precision Estimating computer software and are integrated with accounting through Timberline Construction Gold Accounting computer software,” Rinaldi explains. “Every material purchase, equipment rental and subcontract buy is cost-coded and recorded immediately, creating a single cost-coded system and control tool for every job.”

As each project develops, its costs are continually maintained and tracked by TRG’s project manager, who communicates regularly with the accounting department. “This makes sure that costs are monitored and audited, ensuring they align with the original baseline estimate and ultimately the project budget,” Rinaldi says.

With a successful cost-control system, TRG keeps a watchful eye on the future as well by developing an effective cost-trend analysis method, according to Rinaldi. “As projects move forward, industry trends and market changes are immediately realized, analyzed, documented and managed,” he says. “We not only consider the current project, but remain steadfast as a highly responsible bidder, general contractor and construction management group.”

Latest Projects

TRG’s recent projects include citizenM. The firm is project manager on the 22-story project; the world’s tallest modular hotel ever constructed is slated to open its doors this summer in New York City. Located at 185 Bowery, the 100,000-square-foot citizenM will consist of 210 pods or modular units, totaling 300 rooms.

In addition, it will feature a rooftop, lobby, and plaza amenities. “citizenM is a European hotel developer and operator based in the Netherlands,” Rinaldi explains. “We’re working with architect Isaac Daniel Astrachan from Stephen B. Jacobs Group. Together we are building the world’s tallest modular hotel ever built.”

Typically, modular buildings range anywhere from eight to 12 stories, he adds, noting that this building’s top two stories will consist of structural steel superstructure framing housing a top-of-house bar and amenities lounge. “We’re planning a temporary certificate of occupancy for mid-July,” Rinaldi says.

The high-rise 300-room hotel was built through an extraordinary process. Sealed units containing fully finished hotel rooms were factory-made and stacked together. The rooms were shipped in 210 pieces to New York from Poland. citizenM, which has nine hotels operating and 14 in development, has used modular construction to build the majority of its properties in Europe, where the technique is widespread.

By stacking together the factory-made, sealed units containing completely finished guest rooms, the process allows for faster building – generally about half the time of traditional construction. The number of truck deliveries is also cut by about half, thus significantly lowering the impact on the surrounding neighborhood, according to Rinaldi.

TRG is overseeing construction that consists of a four-story cast-in-place concrete pedestal with a 14-story hybrid concrete superstructure building core and shearwall.

“These pods are built in a controlled atmosphere in a factory, which means the quality control is at its highest level,” Rinaldi says. “All of the mechanical, electrical and roofing is already input into each unit. So when we received them, we basically stacked and connected them like building blocks.

“We make sure that everything works,” he continues. “Modular construction is something that is starting to take root not only in New York City, but also across the United States. A number of the major hotel chains, including the Marriott, are becoming interested in it.”

On Schedule

TRG is also working on HAP8. The New York City project consists of two adjoining 20-story towers, one residential and the other a condominium, totaling 201 units across 310,000 square feet.

“We started construction last spring in April and anticipate completion in late 2019,” Rinaldi says. “It’s located in midtown Manhattan’s Chelsea neighborhood, which is a cultural hot-spot and home to some of the world’s best art galleries, restaurants and bars. It is also close to High Line Park with tree-lined paths and views of the Hudson River.”

A majority of the amenities will be housed in the residential building; however, both buildings will enjoy several amenities including a state-of-the-art gym, swimming pool, yoga studio, childcare center and nearly 100 parking spaces. The condominium will have retail space located on its first floor.

TRG is currently working on the most complicated part of the project, which is the support of excavation and foundation, according to Rinaldi. “We’re driving sheet piling, and it’s a very sophisticated and difficult foundation,” he says. “A lot of this construction is called secant, which holds back neighboring properties and structures.”

In addition, the site still had buildings that needed to be demolished while TRG works on the excavation. “We received different approvals at different times,” Rinaldi explains. “So we had to phase the work that we had done around demolition. This isn’t an easy thing to do because there are crews working immediately adjacent to a building that is coming down.

“It made the sequencing and logistics a bit difficult, but we have been successful,” he continues. “Now, we have captured the entire site and have everything under control. It should get better from this point on.”

He adds that the subcontractors have been great to work with thus far. “Right now the excavation, foundation and superstructure are being done by Sky Materials,” Rinaldi concludes. “They have really done a solid job so far. DXA Studios is the architect and we have worked with them very closely. Their team includes Jordan Ragove and Wayne Norbeck, who both have been outstanding as well. We’re very excited for the final outcome of this project.”

Read more from Modern Home Builder…

The post Modern Home Builder: The Rinaldi Group appeared first on The Rinaldi Group.

TRG Founder and President Anthony Rinaldi appeared on Fox Business Network to discuss how the president’s trade tariffs will affect the construction industry. Video –

The post Anthony Rinaldi on Fox Business: Trade Tariffs appeared first on The Rinaldi Group.

From Hotel Business:

NEW YORK—CitizenM New York Bowery is nearing its official grand opening as the world’s largest modular hotel. Located at 189 Bowery in Manhattan, the Rinaldi Group led the construction of this project.

The CitizenM hotel will have 300 guestrooms; all assembled using sealed, fully furnished, and prefabricated units. The CitizenM is approximately 240-ft. tall, rising 20 stories with 210 pods and a total of 100,296 sq. ft. of space. In addition, there will be an exterior and interior rooftop bar and lounge called CloudM with 360-degree views of the city skyline. There also will be a fitness center, a double-height lobby, lounge and cafe at the property.

Modular construction is one of the fastest growing real estate trends in the country, following its success in Europe and Asia, according to Anthony Rinaldi, founder and CEO of Rinaldi Group.

Among the many advantages to modular construction are the saving of considerable cost and time, which, particularly in Manhattan, limits street closures, keeping them clear and safe for pedestrians, according to the company. Modular construction methods can reduce a project’s completion time by as much as 50%, allowing companies, residents and guests to occupy the space far ahead of the typical building schedule.

“The modular building process can significantly reduce the cost of labor, materials and transportation plus, by its uniformity of design, it minimizes waste,” said Rinaldi. “It’s also superior environmentally and lessens the amount of traffic congestion which is key in urban areas such as Manhattan.”

Read more from Hotel Business…

The post Hotel Business Magazine: CitizenM New York is a Modular Wonder appeared first on The Rinaldi Group.

NY real estate pros say what’s on their minds at the East Mediterranean Business Culture Alliance.

From GlobeSt.com:

NEW YORK CITY—In January, SoftBank led an $865 million investment in Katerra. The upstart company, which plans to transform construction by creating prefab, modular homes in factories, is now valued at $3 billion.

Buildings Constructed in Factories—An Industry Disrupter?

Jeffrey E. Levine, chairman of Douglaston Development, LLC and Levine Builders, visited Katerra’s factory in Glendale, AZ. He described it as a “200,000 square-foot industrial warehouse they purchased on the cheap and fit up with a couple of conveyor belts.”

“It was frightening to me. I didn’t see as much as a pneumatic tool,” said Levine. “But theoretically, they are going to be the people who are going to solve the housing problem in California.”

Levine said he could see this as a solution for low-rise, low-density affordable housing. But he did not see stacking up units as the future for high-rises in dense, urban areas like New York City.

Anthony Rinaldi, the president of the Rinaldi Group agreed, saying modular mass construction works in rural areas, lacking in labor force. “Four, five, six stories with cookie cutters, that becomes something easy to manufacture, should you have a plant.”

However, Rinaldi is building what has been marketed as “the world’s tallest modular hotel,” the CitizenM, a 22-story building located at 189 Bowery. All of the rooms will arrive pre-assembled from Poland. This is expected to not only save on costs but also cut construction time in half.

Levine and Rinaldi joined John Catsimatidis, CEO and chair of Red Apple Group, Faith Hope Consolo, chairman of the retail group, Douglas Elliman Real Estate, and Donna Olshan, president of Olshan Realty, in a panel discussion moderated by Lou Katsos, president of Jekmar Associates, at an East Mediterranean Business Culture Alliance program in the Russian Tea Room. The talk was billed as a “fun, unscripted discussion on the state of development, design and construction in New York and beyond.”

With prefab housing not ruffling any feathers as an immediate real estate industry game changer, what was on the minds of these industry veterans?

The Cost of Construction

Developers say building is economically driven contrasted with architects who may find it art or design-driven. However, developers still want a “wow factor”—while watching the bottom line. Born on a small, Greek Island surrounded by water, Catsimatidis is developing 21-story twin towers with 440 units on Coney Island. Every apartment will have a terrace with a beach view.

Catsimatidis said constructing high-rise condominiums in Miami runs about $150 to $175 per square foot. He compared this to New York, where he noted it can run anywhere from $500 to $1,000 per square foot.

Rinaldi said salaries had become “crazy, ludicrous, absolutely insane,” claiming there are operating engineers making over $400,000. “I paid an operating engineer a million dollars on a project, one man to operate a crawler crane and it wasn’t even a tower crane,” he said. Rinaldi noted if ever there was a time to go to trade school, a skilled craftsman today can make a hefty salary. Carpenters, in the union and not, can earn $250,000 a year, according to Rinaldi.

Levine pointed out awhile back non-union work could be 20% or in some cases 25% cheaper than union labor. But non-union workers’ prices went up as they filled a demand, shrinking the differential to as little as 15% to 10% for high-end residential work. However, with lower level, “stick and brick” work in the Bronx or Staten Island, there will still be a gap of at least 20% between non-union and union pay.

Katsos said nonetheless with some trades including mechanical and electrical work, it is most effective to go to union contractors. With some large HVAC projects, non-union workers cannot do the job. “Good work costs what good work cost. The gap between union and non-union is very small,” said Katsos.

Problems Facing the Industry

“It’s screaming. The market is overpriced and to get it to move, the sellers have to adjust,” said Olshan. Developers get money from the bank, hire a designer architect, and put up a building, according to Olshan. But selling is more complicated and developers need to be more strategic, she said.

“If you’re in the Olympics, the person who is the fastest in the pool wins, right? In real estate, the pool is your sector and whoever is priced the best is the person who is going to win,” said Olshan. She added buildings get built, stay on the marketplace longer, and that’s a problem—and that’s where the industry is now.

Consolo added for retail with new developments, there are certain magnets: Hudson Yards, the Brookfield Center, the Seaport, the World Financial Center. But all of these choices confuse retailers who wonder whether they should go East Side, West Side, Downtown or where they’ll get an underrated deal?

What to Do? Be Smarter.

A retail landlord came to Consolo with 15 buildings and 150 stores, all in Harlem. After three brokers and five years, none had been leased. She gathered a team and looked at the property. “We’re taking this portfolio. We’re going to put one guy on it. I’m going to run it and we’re going to make a campaign,” Consolo told the property management. She created a campaign with her name, “Have Faith in Harlem.” (She received some calls with people asking, “Are you opening a church?”)

Yet the team leased every single store. More importantly, Consolo forged business connections and now sits on the board of directors of the Greater Harlem Chamber of Commerce. But she warns these assignments are not for everyone because they are not successfully completed overnight. For today’s competitive market especially in retail, Consolo advised, “We have to work smarter, more carefully, know who’s expanding and try to figure out the trends beforehand.”

Read more from GlobeSt.com…

The post Unscripted: Catsimatidis, Consolo, Levine, Olshan And Rinaldi appeared first on The Rinaldi Group.

The post The Rinaldi Group Ranked 128 CRAIN’s NY Area Largest Privately Held Companies appeared first on The Rinaldi Group.

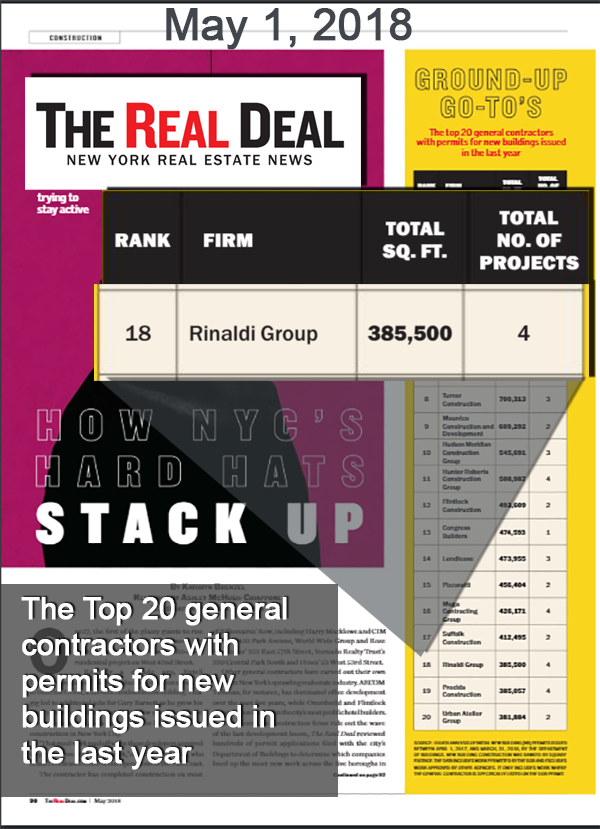

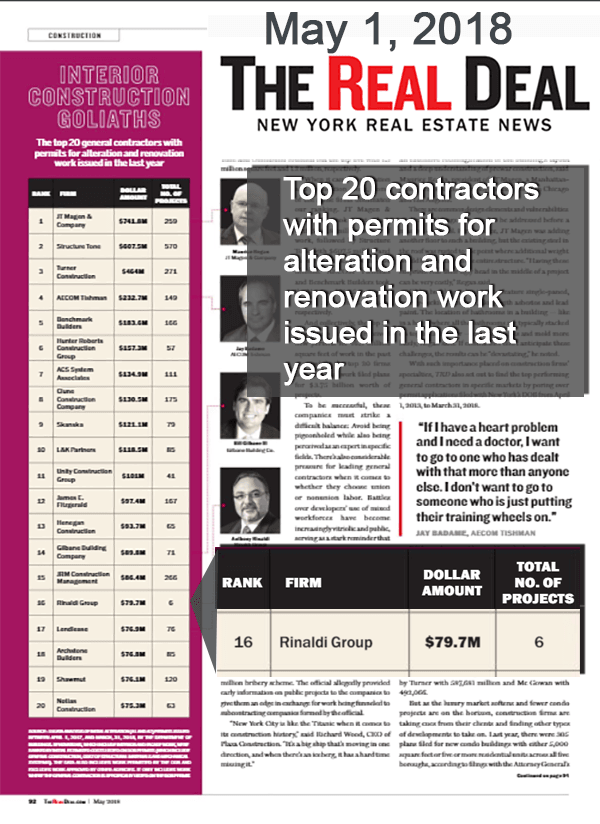

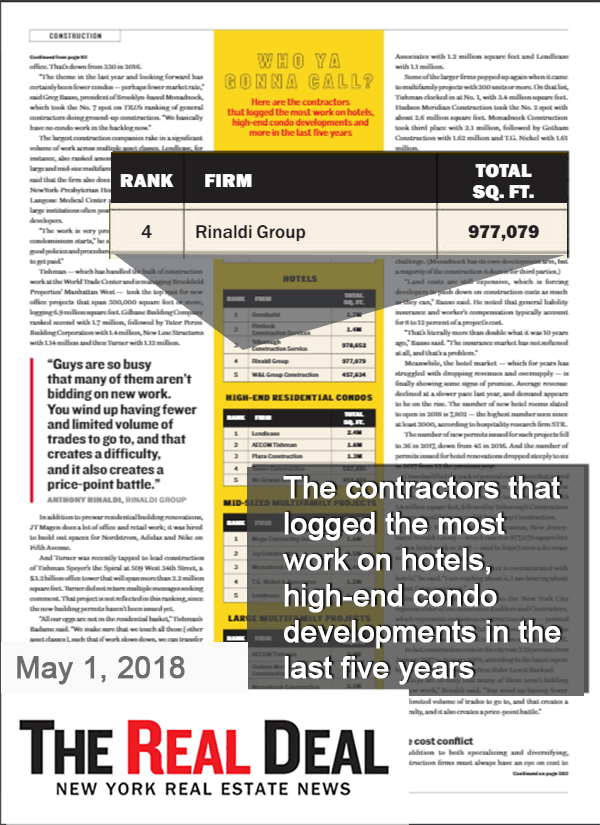

The Rinaldi Group makes The Real Deal charts again in the May 2018 issue. This time, its three charting positions for Top 20 General Contractors (#18), Top 20 General Contractors with Permits for Alteration and Renovation Work (#16), and Most Work Logged on Hotels, High-End Condos in the Last Five Years (#4). Here they are:

The post Rinaldi Group Tops the Charts X3 in May 2018 The Real Deal appeared first on The Rinaldi Group.

The Rinaldi Group (TRG) and DHA Capital are proud to announce the Topping Out of 75 Kenmare. The Rinaldi Group, ranked as one of NYC’s Top Construction Firms, is responsible for the construction and bringing the vision of Kravitz Design, architect Andre Kikoski, and DHA Capital to life. 75 Kenmare is a highly curated collection of luxury residences with breathtaking design and amenities.

The Rinaldi Group (TRG) and DHA Capital are proud to announce the Topping Out of 75 Kenmare. The Rinaldi Group, ranked as one of NYC’s Top Construction Firms, is responsible for the construction and bringing the vision of Kravitz Design, architect Andre Kikoski, and DHA Capital to life. 75 Kenmare is a highly curated collection of luxury residences with breathtaking design and amenities.

Due to the proximity of the MTA, TRG implemented a “Top-Down, Bottom-up” style of SOE/ foundation work. This style of construction offers certain advantages to the project that include reducing the impact on neighboring properties and roadways. It also allows a deeper foundation to be constructed without the cost, time, and disruption of a traditional heel block raker and tie back system. At 75 Kenmare, the cellar and deep sub cellar will provide location for an automated parking system. “The Rinaldi Group prides itself on consistently creating cost-effective ways to overcome the complexities and challenges of urban construction…” said Anthony Rinaldi, President and CEO of the Rinaldi Group.

The Rinaldi Group, founded in 2003 by Anthony T. Rinaldi, an engineer, builder, and licensed safety professional, is a national full-service general contractor and construction management firm, building upon its’ foundation and tradition of self-performance in both the public and private industry sectors alike. Its reputation for performance and execution, practicality with ingenuity, timing, and efficiency, quality, professionalism and safety has grown the firm financially strong and healthy with unlimited capabilities in an industry today more competitive than it has even been before. TRG’s diversity reaches all branches construction, from design-build and core-&-shell to interior fit-out, renovation and rehabilitation, the firm’s abilities are endless.

See more project information and photos here:

The post Grammy Award Winner Lenny Kravitz Interior Designed Luxury Condominium Project reaches major milestone – Topping Out its Superstructure. appeared first on The Rinaldi Group.